The evolution of 3D printing and additive manufacturing technologies has revolutionized the way we create components across various industries. Central to this revolution is the use of metal powders, which serve as the foundational material for creating complex, high-precision parts. In this article, we will delve into the significance of metal powders for 3D printing and additive manufacturing, focusing on two specific types: Ti6Al4V powder and AlSi10Mg powder. Additionally, we’ll explore the broader category of Additive Manufacturing Metal Powder and its impact on the manufacturing industry.

Understanding Metal Powders in Additive Manufacturing

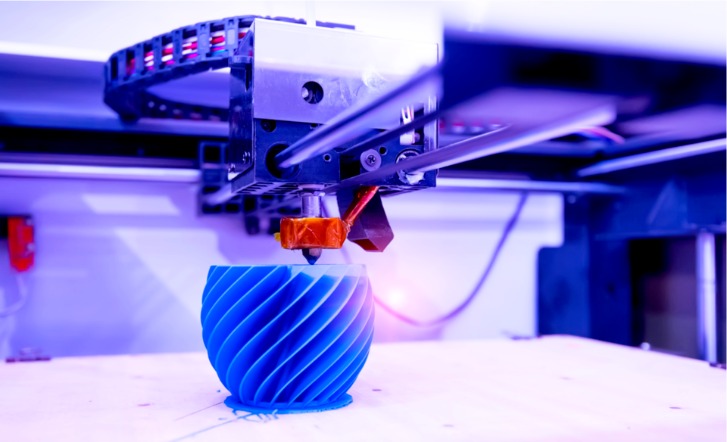

Metal powders are the raw materials used in additive manufacturing processes, where they are laid down layer by layer and fused together to form a solid object. The characteristics of these powders, including particle size, shape, and flowability, significantly affect the quality and mechanical properties of the final product.

Ti6Al4V Powder

One of the most widely used metal powders in additive manufacturing is Ti6Al4V powder. This titanium alloy is renowned for its high strength, light weight, and excellent corrosion resistance, making it ideal for aerospace, medical, and automotive applications. Its ability to withstand extreme environments also makes it a preferred choice for critical components.

AlSi10Mg Powder

AlSi10Mg powder is another popular choice for additive manufacturing, particularly known for its good casting properties. This aluminum alloy provides a fine balance of strength, hardness, and thermal properties, alongside excellent corrosion resistance. It’s often used for creating lightweight parts that require good dimensional stability and high dynamic strength.

The Role of Additive Manufacturing Metal Powder

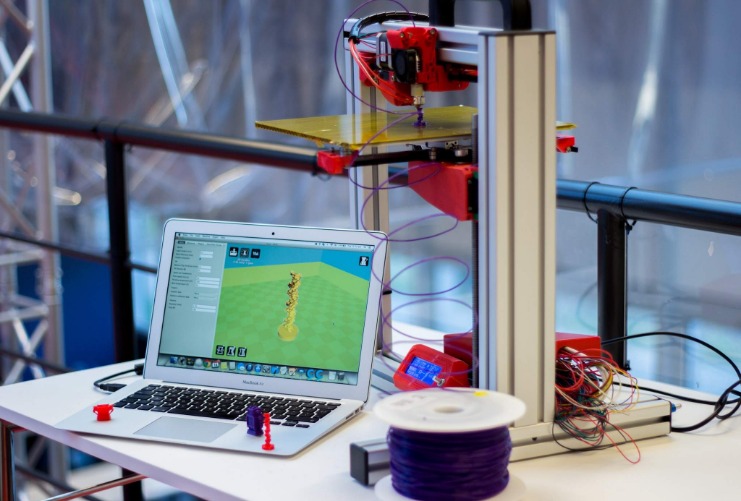

The broader category of Additive Manufacturing Metal Powder encompasses a wide range of metallic materials designed for 3D printing applications. These powders play a pivotal role in enabling technology advancements and innovation in manufacturing. With the right metal powder, manufacturers can:

-

Read more about ti6al4v powder price here.

- Reduce production time

- Minimize material waste

- Produce complex geometries that are difficult or impossible alsi10mg powder to achieve with traditional manufacturing methods

- Customize parts with precision

Read more about Additive Manufacturing Metal Powder here.

In essence, the choice of metal powder directly influences the performance, quality, and application possibilities of the final product.

FAQs

Why are Ti6Al4V and AlSi10Mg powders so popular in additive manufacturing?

Ti6Al4V and AlSi10Mg powders offer a unique combination of properties that are highly desirable in many industrial applications, including aerospace, automotive, and healthcare. Their popularity stems from their mechanical properties, corrosion resistance, and versatility in manufacturing complex parts.

Can any metal be used for additive manufacturing?

While many metals can be used for additive manufacturing, not all are suitable for this process. The metal must be available in a powdered form with appropriate particle size and shape, and it must have properties that allow it to be sintered or melted into a solid form effectively.

How do you choose the right metal powder for your project?

Choosing the right metal powder depends on several factors, including the desired mechanical properties of the final part, the specific additive manufacturing technology being used, and cost considerations. Consulting with material specialists and conducting tests are common practices to determine the best fit for a project.

In conclusion, metal powders for 3D printing and additive manufacturing are critical in shaping the future of manufacturing. As technologies continue to evolve, the demand for high-quality Ti6Al4V powder, AlSi10Mg powder, and other Additive Manufacturing Metal Powders is set to rise, paving the way for more innovative and efficient manufacturing solutions.